CNC Machining Technology

Our company offers comprehensive CNC machining capabilities within a facility of approximately 3,000 square meters, equipped with advanced 3-axis, 4-axis CNC machining centers, including 40 milling machines and 10 turning machines. We offer precision machining services for a wide range of materials—aluminum alloys, stainless steel, carbon steel, copper, and titanium—with tolerances as tight as ±0.02 mm, meeting the exacting requirements of high-precision components.

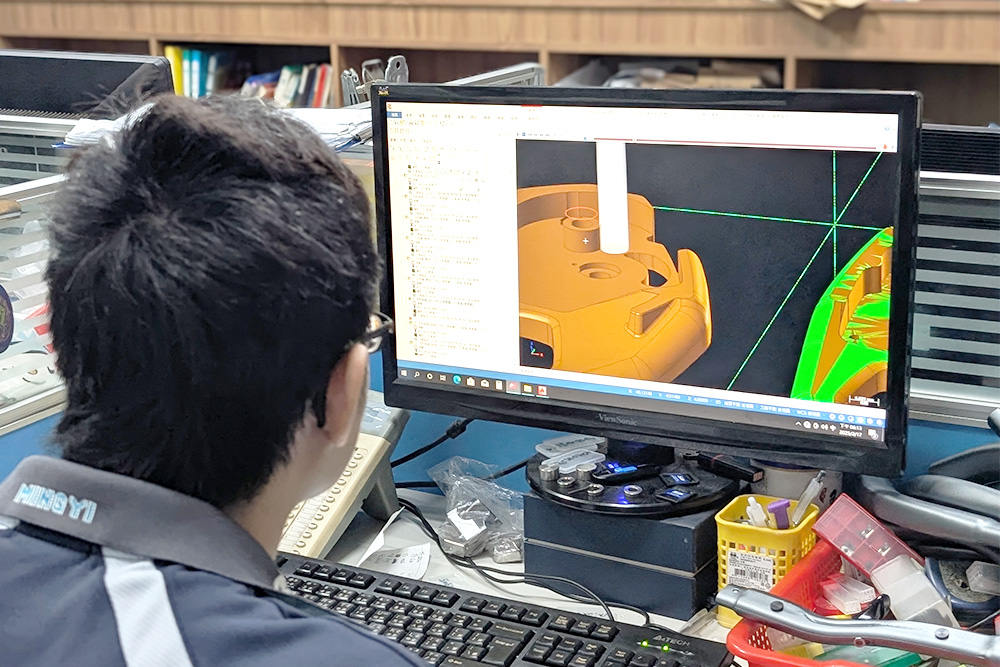

Custom Metalworking Solutions

With in-house mold and jig design capabilities and fully integrated CAD/CAM programming workflows, we provide fast and flexible support for custom development, prototyping, and small to medium volume production of complex parts. Our machining solutions serve diverse industries including semiconductor equipment, medical devices, automotive components, telecommunications, and precision machinery.

Quality Control

All manufacturing processes are conducted under the ISO 9001 quality management system. Our inspection capabilities include CMM (Coordinate Measuring Machine), optical projectors, and surface roughness testers, ensuring strict control of dimensional accuracy and visual quality. Upon request, we also provide comprehensive quality documentation such as FAI, SPC, and PPAP reports to guarantee reliable, high-spec product delivery.